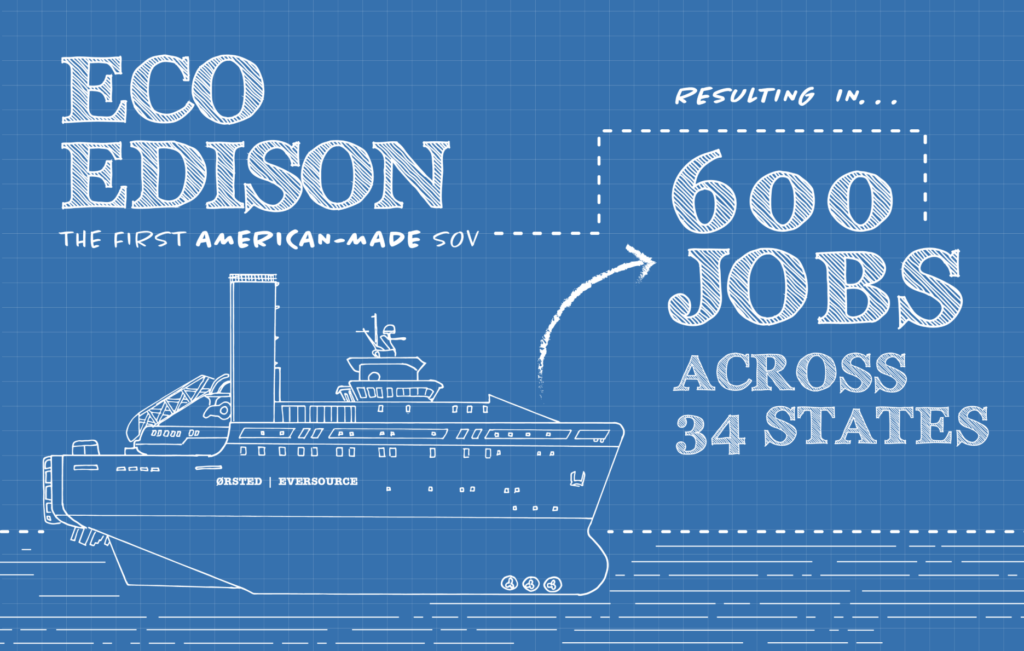

Edison Chouest Offshore (ECO) is playing the long game. In May, the Louisiana shipbuilder christened the first American-made service operations vessel (SOV) for the U.S. offshore wind industry –– the result of ECO’s decades of honed naval expertise and the cultivation of a relationship with clean energy developer Ørsted, among others.

ECO Edison, which was commissioned by Ørsted to support its Northeast projects, helps fill a gap in the growing clean energy industry that demands a fleet of dozens of specialized vessels, many of which must also be Jones Act-compliant. The project also allowed Edison Chouest (ECO) to continue supporting its existing employees, and create new roles that increased its labor pool, ECO’s Vice President of Renewables Michael Braid said.

“We have also opened offices in New York and Rhode Island and will continue to expand our resources in each,” Braid said. “We never underestimate the value and opportunity to keep creating new projects for our team and future hires.”

The May 2024 christening of ECO Edison, the first new-build SOV in the U.S., constructed at the Edison Chouest shipyard in Louisiana. (Courtesy: Edison Chouest)

ECO has been a lynchpin for the industry’s vessel needs, and has supported phases of engineering, construction, permitting, and operations and maintenance (O&M) at South Fork, Vineyard Wind, and Revolution Wind utilizing existing, modified, or new build vessels and services. Combined, their work has resulted in 16 charters totaling about 67 vessel years.

On the horizon, the company will deliver a second new build SOV for the Empire Wind project next summer, and in 2026 will complete two, new build articulated tug and barge feedering vessels in support of Maersk’s new wind turbine installation vessel (WTIV). ECO was also recently listed as Avangrid’s preferred supplier of a new build SOV to support the developer’s New England projects.

Oceantic Network spoke with Braid about ECO’s journey in offshore wind. From their initial engagement with Ørsted to the delivery of ECO Edison, the interview offers a look at the factors that drew the company into the industry, what’s keeping them there, and what the future might hold for the legacy Gulf shipbuilder. Let’s dive in.

Oceantic: When did you identify offshore wind’s potential for new business growth?

Braid: We have been monitoring the sector’s rapid growth in Europe through our joint venture partner Island Offshore for the last 12-15 years. We were always confident that at some stage the U.S. sector would flourish, so we positioned ourselves early to move with the tier-1 contractors so that we earned experience through the first wave of projects. We have been very fortunate to work with established contractors on wind farm engineering, procurement, and construction services in the U.S. such as Boskalis, Jan De Nul, DEME Group, and Nexans. They have been excellent partners to work with; their depth of knowledge and experience in the sector is unparalleled, which allows us first-hand experience to learn from the best in this new and burgeoning sector.

Our first engagement was with Ørsted for their long-term SOV at South Fork, Revolution, and Sunrise offshore wind farms back in 2018-2019. We ended up executing a contract with them in 2020 and have since worked very closely with their teams and expanded our services to them across multiple verticals. The first project we undertook was with DEME using the Laney Chouest to plough at South Fork ahead of their vessel laying export and array cables last year.

Oceantic: What factors did you consider when you decided to take on the ECO Edison project?

Braid: When we look at new build projects, we first look at the intricacy to measure competitiveness, and then it’s really down to who the client is. We model ourselves on long-term relationships, therefore this project being a “first of its kind” in the U.S. with a leading player such as Ørsted, was very attractive.

Oceantic: Why was Edison Chouest well-suited to take on this project?

Braid: This project was a perfect example of how a vertically integrated organization can add more value and de-risk very sensitive projects. We held all the critical components for this in-house and leveraged our capabilities, so the client and project realized this was the only viable solution.

- We design our vessels in-house with our team of naval architects and engineers and have been doing so for decades.

- We have our own dedicated U.S. shipyard group covering four yards across three states that build exclusively for ECO.

- We have our own marine procurement affiliate that supports our nearly 300 strong fleet, which delivers purchase power and efficiencies.

- We own our own component suppliers such as Marine Technologies, which provides dynamic positioning and control systems for the bridge, communications systems, and the control systems for the integrated gangway system.

- We employ our mariners directly and train them in our facility in Louisiana, providing them with free access to continue their career trajectory and performance growth.

This is not exhaustive, but showcases what separates us from any other offshore ship owner in the world.

Oceantic: How does ECO Edison compare to other vessels ECO has built in the past?

Braid: We covet complex projects because we can utilize our full breadth of capabilities, and ECO Edison certainly delivered that! It isn’t the largest project we have taken on, but Ørsted was clear in their targets for how the SOV would operate so we knew it was going to be a very close collaboration to achieve those efficiencies. We have built a cruise ship and delivered many yachts from within our wider group, so we knew we had the experience and capabilities in-house to deliver the high-quality accommodations and amenities the client required.

Oceantic: What new elements did the project present?

Braid: Designing, then building, a vessel with an integrated motion-compensated gangway was new for us, but the team at Ulmatec worked closely with us so we could undertake as much as possible from the U.S., such as building the tower ourselves and delivering our own control package. We also built the aluminum workboat, which is a 12-meter Chartwell design –– another first for us. We select our partners closely, so we had comfort in the end product meeting the quality we and Ørsted require.

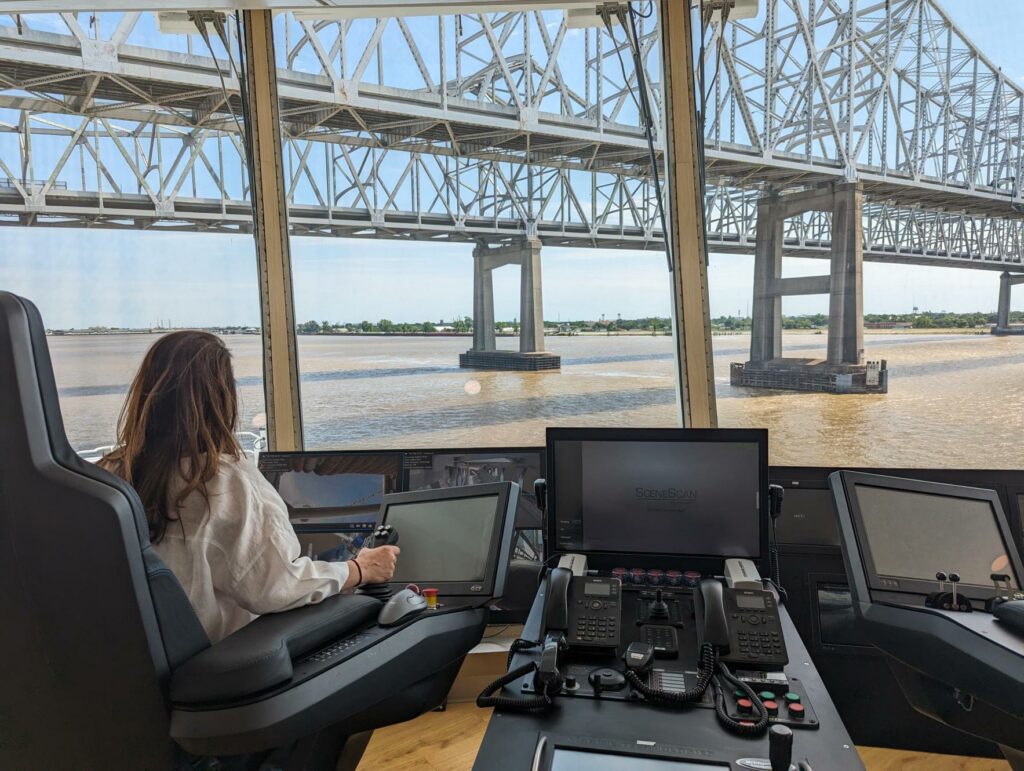

Liz Burdock, President and CEO of Oceantic Network, tours the ECO Edison vessel.

Oceantic: How do you envision your role in offshore wind going forward?

Braid: We have a target of providing integrated marine-based services through a single contracted American solution covering subsea, marine logistics and topside integrity management. ECO will be looking to offer full O&M-based services in the future, so watch this space.

Bonus Question: Have you given a name to Eco Edison’s new mini-CTV?

Braid: TEE ED, which means little Ed, referencing big Ed being the ECO Edison.

The U.S. offshore wind vessel fleet is quickly expanding with four new crew transfer vessels (CTVs) launched in the first quarter of 2024, and construction of the first U.S.-based wind turbine installation vessel nearing completion. Read the latest updates on the industry’s steel and shipbuilding supply chain in Oceantic Network’s Quarterly Market Report.